The Bartolomei et al. experiments [1] were carried out for verification of models that are used to describe thermal-hydraulic processes in steam generating pipelines. The verification experiments investigated variation in void fraction, j, along the length of a vertical heated pipe with subcooled boiling of water.

The experiments were performed in a closed-loop setup. The setup comprised a flow channel with circulation pump, electrically heated heat exchanger for controlling the water temperature, test section, and separator. Steam downstream of the separator flowed through condenser and condensate cooler to the circulation pump suction header. Separated water also flowed through its cooler to the suction header. The setup was equipped with makeup system and pressurizer.

The test section was a steel pipe of 12 mm inner diameter and 2 mm wall thickness with upward fluid flow. The pipe was heated by alternating electric current supplied through copper leads. The experiments measured pressure, mass velocity, heat flux density, and temperature of water at the pipe inlet. Void fraction was determined by g-radiography. Signals were continuously recorded as the radiography unit was smoothly moved along the channel and provided void fraction measurements at any cross-section. The maximum relative errors of measurements were 0.01, 0.02, and 0.03 for pressure, mass velocity, and heat flux density, respectively, and the maximum absolute error of temperature measurements was 1К. The experiment conditions were controlled within specified parameter limits. The observed deviations were a maximum of ±0.05 MPa for pressure, ± 1% for mass velocity and power, and ±1 К for inlet temperature.

Input data

The flux density was kept uniform over heated 0.8 m – 1.5 m long test pipe lengths. The variation ranges of the experiment parameters were:

- pressure – from 3 to 15 MPa;

- heat flux – from 0.4 to 2.5 MV/m2;

- mass velocity – from 400 to 3000 kg/m2/s.

The parameter values chosen for the calculation are given in the table below.

| Qmax, MV/m2 | P1, MPa | Tin, 0К | ρw, kg/m2*s |

| 0.77 | 14.74 | 598 | 1847 |

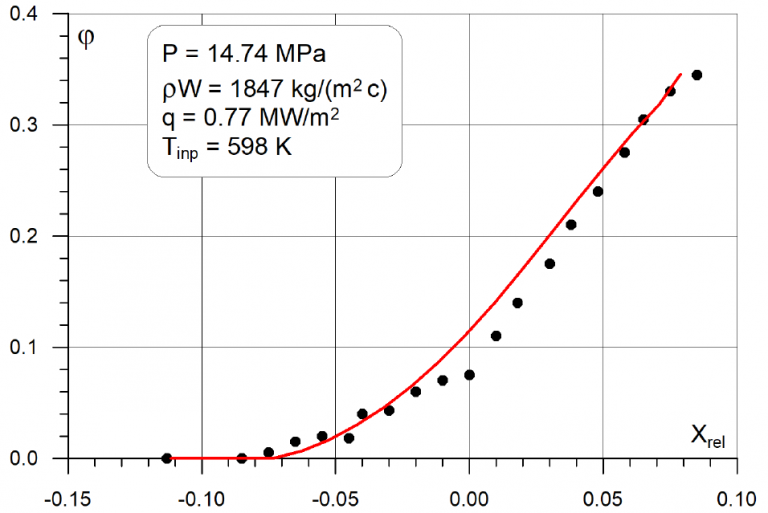

Experiment data for the conditions of [1] are shown in the figure below:

The experimental points are summarized into the table below for convenient comparison of calculation results with experiment data:

| xrel | -0.113 | -0.085 | -0.075 | -0.065 | -0.055 | -0.045 | -0.04 |

| φ | 0.0 | 0.0 | 0.005 | 0.015 | 0.020 | 0.018 | 0.040 |

| xrel | -0.03 | -0.02 | -0.01 | 0.0 | 0.01 | 0.018 | 0.03 |

| φ | 0.043 | 0.060 | 0.070 | 0.075 | 0.110 | 0.140 | 0.175 |

| xrel | 0.038 | 0.048 | 0.058 | 0.065 | 0.075 | 0.085 | |

| φ | 0.210 | 0.240 | 0.275 | 0.305 | 0.33 | 0.345 |

Nodalization scheme

Nodalization schemes are graphic representations of simulation models. The figure below shows a typical nodalization scheme that is used for modeling an upward water flow in an electrically heated vertical pipe. The vertical flow is here simulated by channel CH1 element whose inlet connects to blocked junction BLJUN1 element and outlet to boundary volume BVOL_T1 element. Channel CH1 is divided into 21 control volumes, or simply volumes. Mass source SMASS_T1 element sets the rate of water inflow to the first volume of channel CH1 according to the tabulated value of ρw. The pipe body is simulated by heat conduction structure HCS1 element. The heat conduction structure is radially divided into 3 computational nodes and axially into 20 volumes. Heating of the pipe is modeled by heat conduction structure power QHCS_T1 element. The outer thermal insulation surface is simulated by heat transfer boundary condition BHEAT1 element.

KORDAT input file

The kordat input file is a program that is created in DLC language according to the generated nodalization scheme. The input file contains procedures for describing connections between elements (LAYOUT procedure) and single-valuedness conditions for each nodalization element (DATA procedure). In addition, the input file contains OUTPUT procedure for generating a calculation output list and EVENT procedures for setting an increase in heating power and flow rate to specified values. The EVENT procedures are also used to generate simulation parameters from typical values that are calculated for each element.

Entries in the kordat file can be the following:

KUTDAT input file for the KORSAR utility

KORSAR calculation output is written to the korres external file in binary form. A service program (utility) is provided for representing calculated data in text form (parameter tables). The KORSAR utility, kutil2.exe, uses its input file, kutdat, where settings are written in text form in the DLC language.

The utility input file is written in the DLC version only containing the main procedure and OUTPUT procedure descriptions but no DATA, LAYOUT, and EVENT procedures.

The main procedure in the utility input file generally includes:

- assignment of values to the procedure keys;

- declaration of variables and optional calculations;

- output statements before the beginning of cycle over time;

- BEGIN…END block – cycle over time of records in the result file;

- output statements after the cycle over time;

- END statement.

Any part of the procedure except the last END statement may be omitted. The absence of BEGIN…END block indicates no cycle over time of records in the korres file.

The BEGIN…END block organizes a cycle over time of records in the korres file.

An utility’s OUTPUT procedure can be called by OUT statement from the main procedure including the BEGIN…END block.

If there exists at least one WRITE or WRITE1 control statement within OUTPUT procedure, a file will open with the name that is the same as the name of the current OUTPUT procedure and each WRITE (WRITE1) statement will write one string into this file.

It is preliminarily found that calculated balance and actual void fractions do not almost change with time after 20 s run time. Therefore, assume that the steady state in this problem is reached at ~ 20 s and write the void fraction values after 20 s to calc.dat result file using the following kutdat file:

Comparison between calculation results written to calc.dat file and experimental data is illustrated in the figure below:

References

- Bartolomei, G.G., Brantov, V.G., Molochnikov, Yu.S., et al. An experimental investigation of true volumetric vapor content with subcooled boiling in tubes. – Thermal Engineering, 1982, No. 3, pp. 20-22. .

- KORSAR/V3 – User Manual. – NITI, 2019.